What Is Order Management?

Order management is the process of receiving, tracking, and fulfilling an order and shipping an order to a customer, business, or intermediary. It's simple to define, but its complexity is easy to underestimate. The process begins and ends with the customer experience. If something goes wrong during order processing, informed customers want immediate access to what's wrong, a response regarding availability if a product is lost, unavailable, or out of stock, and a level of service that matches their expectations.

Managing the life cycle of an order requires time and resources, including systems, software, and designated processes. The optimization of order management occurs when the discipline provides value to both a business and a customer by ensuring that ordered goods or services arrive on time and accurately.

The life cycle of an order occurs in different environments — from digital e-commerce applications, warehouses, third-party drop-ship facilities, and shipping companies to delivery intermediaries. The retail industry supply chain best represents the cycle, because it is where positive customer experience, for business-to-business (B2B) or business-to-consumer (B2C) operations, is the primary outcome. Of course, the life cycle of an order is a core process in the supply chain operations of many industries, including healthcare, technology, finance, manufacturing, and entertainment.

Ordering Management Process Templates

The document management process in order management is critical to the customer experience. Avoid wasting valuable time and resources in your workflow, and standardize your order processing documentation with these free, downloadable templates.

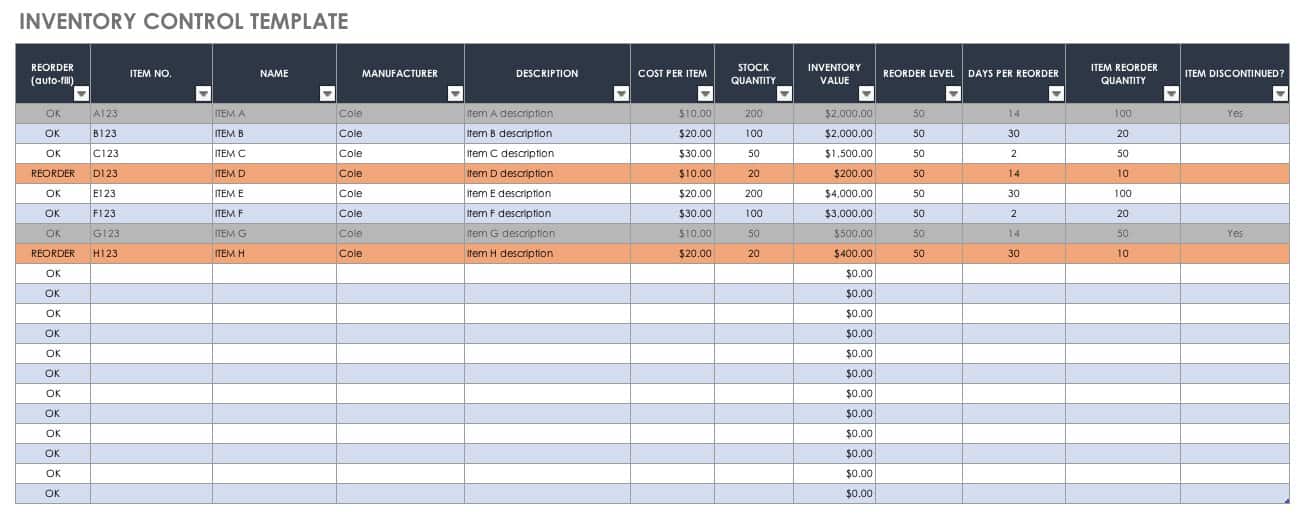

Inventory Control Template

Inventory management is a core function of order management process and technology. Use this Excel template to track inventory status, including product availability, and restock levels. This template is customizable to match your order management needs.

Download Inventory Control Template

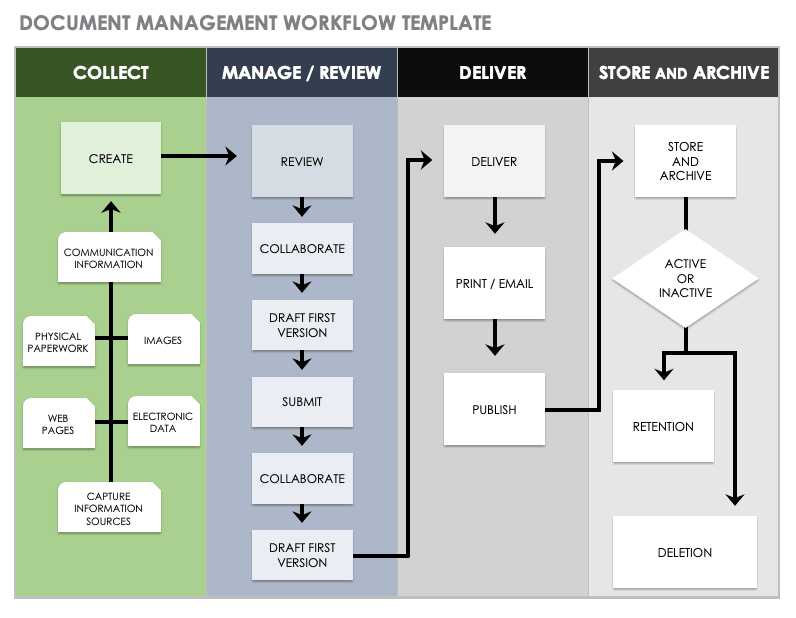

Document Management Workflow Template

Use this template to manage, submit, and store documents, both in their physical and digital forms. With space to include everything from document creation to publish date and archival location, you can safely manage and track all documents using this streamlined workflow template.

Download Document Management Workflow Template

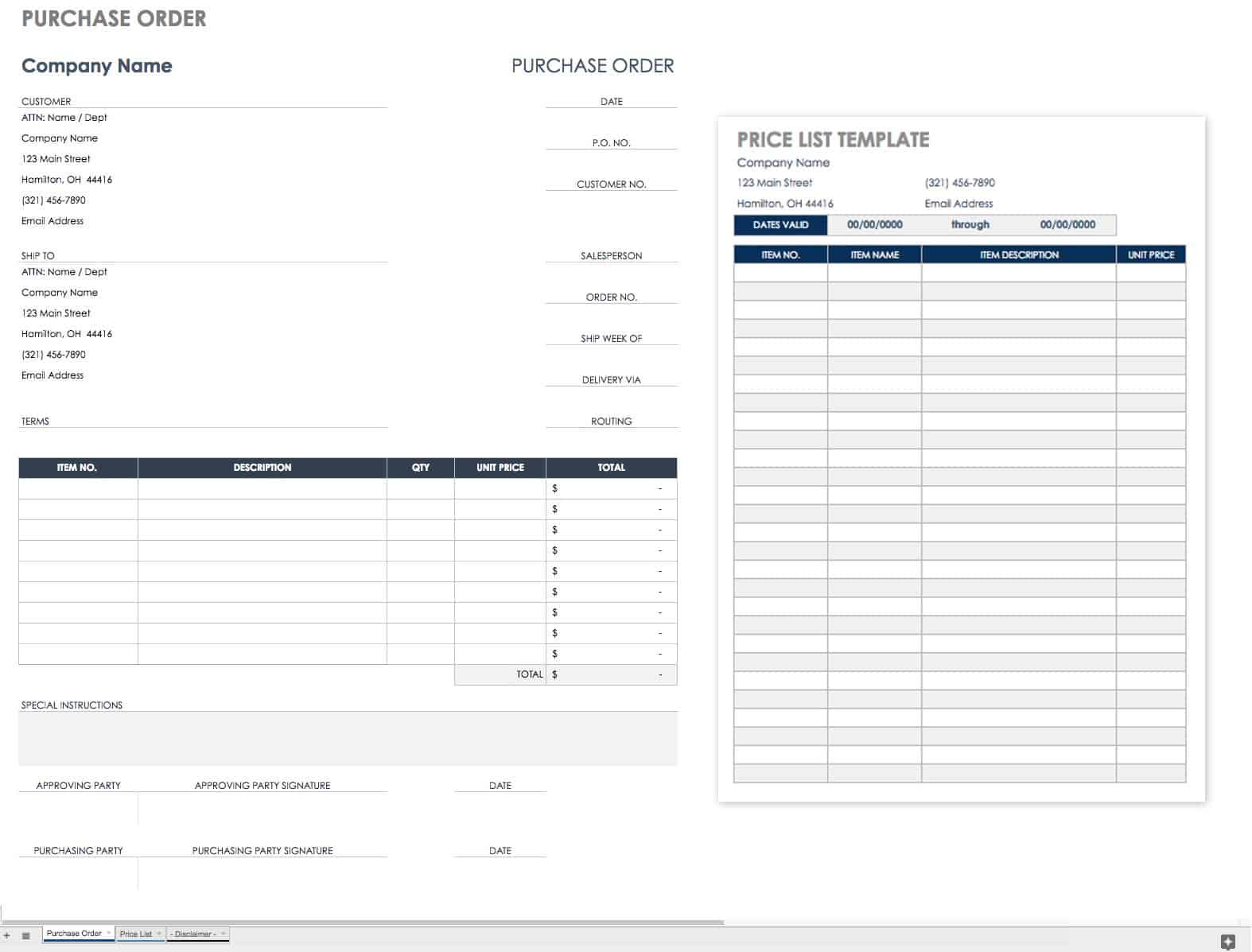

Purchase Order Template

Use this purchase order (PO) template to bridge the gap between OMS implementations, or to save to your order crash kit should your system go down. The template allows you to include images for better order accuracy, or to aggregate like products (such as parts) on one PO. This template is available as an Excel, Word, or PDF file.

Download Purchase Order Form with Images

Purchase Order with Price List - Google Sheets

Purchasing is a core function of effective order management. Use this purchase order template to compile accurate price lists to expedite the purchasing process. It is designed so you can create and update separate price lists for multiple vendors. You can save this Google Sheets template and print it as a PDF file.

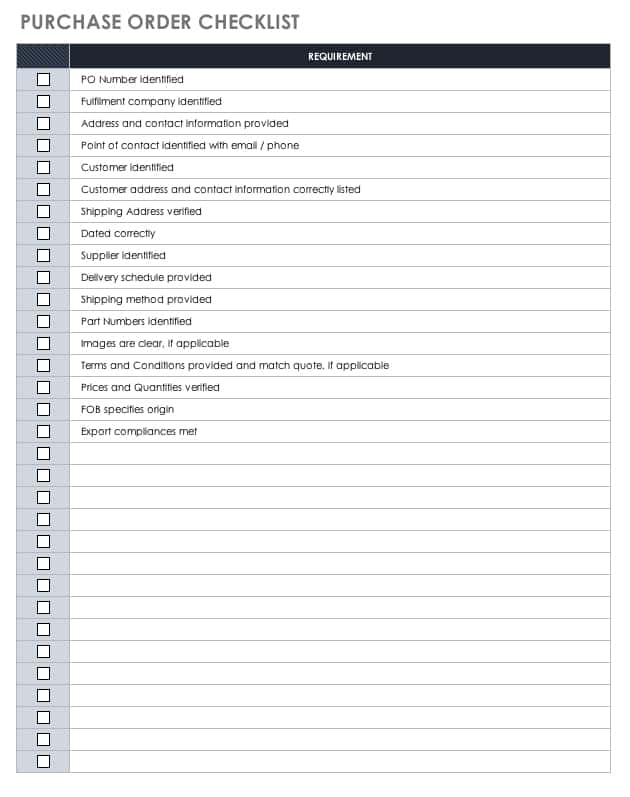

Purchase Order Checklist Template

If you’re implementing new order management processes or systems, use this free purchase order checklist template to guide employees and customers through creating and submitting POs. Include the new PO requirements and processes that match your order management process so your customers have a clear understanding of new requirements.

Download Purchase Order Checklist

Purchase Order Tracking Template

Use this purchase order tracking template to keep track of outstanding orders by PO number, vendor name, payment status, and delivery dates. It is designed with a filter for individual suppliers, outstanding payments, and more.

What Is the Order Management Process?

In his book, Essentials of Supply Chain Management (4th Edition), Michael H. Hugos defines order management as the process of communicating information throughout the supply chain, starting with customer orders and moving back through a supply chain made up of retailers, distributors, service providers, and producers. The order management process shares information such as delivery dates, product availability, and general order status communication.

Hugos has advised and mentored development teams for organizations like Microsoft, Starbucks, and the U.S. Navy. His company SCM Globe provides cloud-based supply chain modeling applications for academic institutions, business services, humanitarian relief, and military logistics.

The Order Management Life Cycle and Process Flow

The order management process flow lives in the supply chain management ecosystem. The fundamental business services that makeup this process flow involve the following supply chain practices:

- Order placement and data entry

- Payment processing

- Order fulfillment

- Inventory and warehouse management

- Picking and packing

- Shipping and delivery

- Carrier control

- Customer order tracking

- Returns and refunds

In some organizations, order management is a standalone job title, with various title renditions (e.g., order management specialist or customer order management specialist). For more on customer order management professions, see this customer order management article. Outside of specific tasks and responsibilities related directly to order management roles, the order management process flow incorporates various business functions and people, including the following:

- Sales and Marketing: The process of attracting, improving, retaining, and expanding customer orders

- Customer Relationship Management: The record of the sales and marketing processes, including customer (and vendor) data that involves customer relationship management (CRM)-related functions and systems

- Accounting and Back Office Operations: Accounts receivable/accounts payable processes involving purchase history, purchase, change, work orders, payments, invoicing, receipt, and back ledger operations

- Logistics and Warehouse Management: The order fulfillment process, including inventory management, shipping, and delivery

- Information Technology and System Operations: The management of electronic systems, software, hardware, and databases related to customer orders

The History of Order Management

To better understand the new paradigm of order management, and the value of modern order management systems, it helps to evaluate the history and characteristics of traditional order processing. Before modern web-based inventory and order management platforms, organizations relied on telephones and outdated paper document management of purchase orders, work orders, change requests, warehouse pick tickets, shipping manifests, and invoices. Relying on paper document management made accessing valuable business intelligence tedious.

The advent of electronic commerce and direct business-to-customer order processing from catalog sales gave rise to early catalog management systems. Customer service representatives (CSRs), working from a siloed department as an extension of a sales and operations team, took orders by phone, fax, and eventually email. Determining workflow status, finding a customer the right product, or inquiring about shipping or billing details required multiple queries, with different stakeholders across different teams. Long workflow lead times and lags in shipping and delivering to customers in larger geographical markets created demand for another siloed team of CSRs. One team might handle customer complaints, account management, warranty issues, and returns, while another siloed team, located in the warehouse or factory, might be responsible for order fulfillment, inventory management, packaging, shipping, and tracking activity.

The New Paradigm of Order Management

SCM Globe’s Hugos opines that supply chains are evolving and becoming more complex. For order management, this means customer response times increase in sync with customer service expectations. The global digital economy (and the e-commerce markets that define it) is made up of multiple tiers of suppliers, vendors, managed service providers, multichannel distribution partners, and third-party drop-ship intermediaries. These parties have an increased level of expectation for the business services involved with the order management process.

To compete and evolve with new supply chain complexity and changing markets, Hugos advocates for a new paradigm of order management that relies on faster, more accurate, and more responsive exchanges of digital order data. He recommends four order management principles:

- One and Done: The process of capturing an order and entering it into the system should happen once, without manual steps for reentering data, and as close to the source as possible. For example, online orders entered by the customer create order data that moves through all systems and communicates to all supply chain participants without any intervention in order to create purchase order or invoices.

- Automated Routines: To spot problems and provide real-time information, Hugos recommends automating routine order processing. Doing this frees up your CSRs or account management team to shore up essential business services related to inventory shortages, delayed delivery, or customer change requests. Learn more about automation and other technological innovations of modern OMS in this section.

- Order Visibility: Vendors, suppliers, and customers should not need to contact your people to view the status of an order. If problems occur, such as an inventory shortage, your order management system needs to alert the appropriate CSR for resolution, so they can communicate to all parties without being prompted by the customer.

- Integrated OMS: Connect systems and integrate software to create a platform for order management that is accurate and provides real-time status on products and orders. The applications that manage customer-facing content, data, and pricing need to automatically flow with applications (used to update inventory status, calculate delivery schedules, and generate invoices) into a single source of information.

What Is OMS?

Order management is a business practice and a type of software technology. The term order management systems (OMS) refers to standalone software applications, or end-to-end software platforms, that merge business practices concerned with three areas of operations: sales, order fulfilment, and accounting. In conversation, someone using the term OMS is likely referring to the software application(s) they use to aid their business in inventory management and customer communication.

Order management systems are useful as a type of business infrastructure and as a business strategy to optimize customer interactions.

A fully integrated order management system, for example, an enterprise resource planning (ERP) suite, might incorporate some (or all) of the following functions:

- Content management (product information, promotion, pricing)

- Inventory management (location, quantity)

- Vendor management (supplier purchasing)

- Sales and marketing (customer relationship management)

- Customer database (analytics and business intelligence)

- Accounting (payment processing and invoicing)

- Order fulfillment (picking, packing, and shipping)

Some vendors offer integrated suites with a large number of modules, while others specialize in one or two particular functions. Most, however, include the following core functionality: catalog management.

What Is Order Management Software?

The term order management system is often used to describe the functionality of software applications embedded within the larger ecosystem of CRM, ERP, and SCM systems. OMS is also used to describe a class of standalone software applications, often integrated with the larger ERP systems, that take advantage of features and processes related to order fulfillment, customer communication, and work order management. These tools bridge the gap between order entry, processing, tracking warehouse operations, accounting, and business intelligence.

Digital, web-enabled commerce, social media advertising, and mobile devices with payment processing applications completely changed the demand for order management software functionality. Modern order management software is designed with functions that enable a single ordering agent or CSR to deal with the end-to-end order management for a multichannel business. Enhanced technology, like order process automation and integrated document management, transforms individuals into order management superheroes, capable of resolving more customer problems with less interruption and with less interaction with other stakeholders.

Who Buys Order Management Software?

The market for this technology includes small business owners, manufacturers, retailers, wholesalers, entrepreneurs, e-commerce sellers, and brick-and-mortar operations. Order management software helps businesses of any size or scale in the digital economy manage supply and demand for their products at the right place and the right time. Using retail as an example, OM software touches multichannel business services, from order entry and tracking and inventory stock and logistics to packaging and shipping. Other industry domains served by OM software vendors include the following:

- Retail

- Wholesale distribution

- Banking and financial services

- Healthcare

- Hospitality and food service

- Manufacturing and automotive

- Transportation

- Telecommunication

Order Management Software: An Application for Every Step

The supply chain is an ecosystem of integrated processes and business services. Modern OMS platforms can streamline order entry, processing, and fulfillment of orders, from the point of sale to payment processing and delivery, and enable real-time communication to manage all aspects of a multichannel business. This system creates methods for managing customer call center support, customer relationship management activity, purchasing, sales forecasting, inventory and warehouse management services, product marketing, and accounting functions.

A unified OMS also provides a single source of information to manage and analyze order management-related supply chain data. By automating the search for inventory by region and providing customers with multiple options for shipping rates and carrier availability, Amazon uses an integrated OMS to optimize the online customer experience. Reducing errors, eliminating manual customer service steps, and gaining access to specific business intelligence with an integrated system replaces the need for multiple standalone applications.

Enabled by digital communication, customers stay connected to their orders at all times and expect the companies they spend money with to do the same. Failure to deliver on time or provide the right product is a surefire way to lose customers. Now, failure to communicate each stage of the order fulfillment process to the customer carries the same risk. Thankfully, there is a type of application and system architecture designed for the order management process.

Order Management Microservices

Individual services that touch multiple business channels throughout the order management process are the backbone of large-scale enterprise resource platforms and customer relationship management systems. Easy-to-automate business services — payment processing, customer logins, inventory search engines, and customer notifications — are good candidates for a type of software application architecture, or framework, know as microservices. Microservices refer to software applications that are designed around independent business capabilities, but built to serve as end-to-end platforms.

Amazon helped popularize this type of architecture in order to divide the business capabilities of its most profitable product, Amazon Web Services (AWS). Using the steps from this order management process flow example, a hypothetical retailer uses microservice-based OMS with the following independent, backend services (business-facing events, like storing and manipulating data) for its online website:

- Order Placed: A sales rep, CSR, or customer creates an order event on a mobile device, back office sales order system, or B2B web portal. With microservice architecture, the order event kicks off a series of OM services. Eliminating manual data entry and document management eliminates cost redundancy and paperwork and increases the accuracy of order processing activity.

- Order Data: The first business service event is the order data stored and saved in the database. This database of vendor and customer records acts as the defacto CRM. Stored data is used for internal general ledger activity involved with account history, customer terms, billing, payment processing, back ledger data, discounts, and promotional codes.

- Order Fulfillment: Microservice architecture provides visibility for the entire order processing lifecycle, from initial order event through internal fulfillment actions, like stock reorders, inventory caching and counts, invoicing, and payment. Ideally, at this stage, the OMS automates all communicated business services to manage, allocate, pick, package, and ship orders across all inventory classes and available SKU assets.

- Order Delivery: The proper documentation for carrier, billing, and scheduling is stored as a delivery event. The OMS processes a carrier event to control shipping status and create updates for the customer as well as all involved departments. This service monitors real-time delivery status for omnichannel business supply chains involving multiple brick-and-mortar inventory, warehouses, and regions. If there is a delay due to bad weather, a change in carrier, or changes in freight classifications, then the OMS communicates updated billing and payment events.

- Order Follow-Up: A service event creates automated customer service notifications confirming the order event, email marketing communications (customer opt in), and order tracking. After delivery, customer service notifications handle help requests and follow-up services, like returns, exchanges, refunds, and customer rewards points tracking.

- Order Metrics: The microservices system creates a series of actions, starting with the order event, to measure and analyze internal analytics related to business processes, performance data analysis, digital advertising data, and CRM metrics and sales trends.

Additional Order Management Software Business Capabilities

The logistics-oriented organization depends on effective supply chain management. Order fulfillment is a core supply chain process on a global scale. An OMS platform that integrates all phases of the order management process (from order through delivery) is capable of generating information that flows from the market to the supply chain on demand. The capabilities of order management software are shaping the way organizations respond regarding internal business services, product offerings, and customer service. OMS vendors advertise a range of product functionality that their software possesses, including the following business capabilities:

- Security: Processing payment, involving multiple regions, online and mobile payment vendors, and currency exchange

- Order Routing: Managing by regional warehouse proximity, common carriers, and delivery destination in order to expedite and optimize shipping

- Platform Integration: Software compatibility with internal legacy systems and companies like Amazon, eBay, Etsy, and Shopify, as well as carriers like UPS and FedEx

- Supply Side: Supplier management and tracking to monitor purchase and sales orders

- Third Parties: Notifications for third-party logistics (3PLs) intermediaries in order to manage freight, shipping batches, and expiration dates

- Demand: Inventory demand forecasting and sales reporting for strategic restocking fill rates, inventory turnaround, and purchasing

- Packaging: Label creation, packaging coordination, and post-shipment document management

- Hardware: Wireless device compatibility from anywhere with the iPhone, iPad, tablet, and laptop catalog and work order management

- Customer Satisfaction: Personalized customer service features for customer loyalty/rewards program and automated email notifications

Order Management System Trends and Technology from the Pros

“Companies that automate their order management will see a great impact in terms of customer experience, because everyone wants to know that an order they place is being processed immediately,” says Smith. “There is no reason to ask your customers to change the way they send you orders, and the process should be as simple as possible for them,” he continues. “As you use the system, the solution should then have the ability to easily ‘learn’ the different formats. In this scenario, there’s no need for expensive templates, which will be of no use if the customer changes their format over time.”

In Smith’s opinion, AI will greatly reduce manual order entry steps beyond currently available OMS technology. “Any solution you look at should have, at a minimum, machine learning technology, which learns from the changes made by the person entering the order,” Smith notes. “Machine learning is now advancing to ‘deep learning’ technology, which utilizes the neural network and can intelligently predict, without human intervention, how the order should be managed.” AI disrupts existing processes ordinarily performed by people by creating new forms of machine-driven interaction between companies and customers.

“With the right order management technology, you can greatly reduce the time it takes to enter orders and manage order volume growth without the need to add more people,” says Smith. There are several supply chain trends to watch as organizations adopt new technology and OMS vendors innovate to keep up with market demand. Faster, more accurate supply chain operations rely on the adoption of order management processes and technology that are capable of handling the digital economy’s increased speed and volume of orders.

- System Convergence: OMS vendors are aligning with the demand for and market growth of unified omnichannel systems that handle supply chain planning, execution, and visibility. For example, the trend to integrate traditional OMS capabilities with the sales and marketing services of CRM systems creates a hybrid system capable of improving order response times.

- Robotics: Industrial robots working in factories and warehouses are more affordable and more capable. Companies of all sizes now have access to programmed robots that can move inventory without rest and with improved durability. Using central intelligence and sensors to alert robots of people or obstacles in their paths, warehouse automatons improve the speed, efficiency, and safety of the order fulfillment process.

- Driverless Carriers: The digital supply chain requires enhanced efficiencies that match the demand for customer-centric delivery options, including flexible scheduling, rapid delivery, and streamlined returns. Delivery drones and driverless freight vehicles make managing 24-hour, rapid order fulfillment and transportation a possibility.

- 3D Printing and Manufacturing: Improvements in the cost and availability of 3D printing technology present a unique order management challenge. Companies like Tesla, using advanced 3D material manufacturing, can build unique vehicles designed by a customer. In theory, Tesla needs a customized, on-demand order management process and an OMS to allow customer-driven order entry and handle unpredictable material demand.

- Artificial Intelligence (AI): AI is creating a more efficient digital supply chain by using simulation modeling capabilities and predictive analytics in order to spot trends in massive amounts of data. The effects of this technology threaten changes and the availability of traditional ordering management process jobs in the physical supply chain. An OMS that uses machine learning algorithms to run supply chain simulations frees up people to improve day-to-day operations involved in order fulfillment.

- Internet of Things (IoT): Wireless-connected warehouses and factories equipped with mobile devices, like radio frequency identification (RFID) tags and automated sensors, provide unique order management solutions, while also minimizing infrastructure changes or space requirements. IoT-connected devices can gather large amounts of data in real time and collaborate with AI-driven databases to react to the speed and demand of a digital economy.

- Big Data: IoT-connected devices and AI-powered systems create massive quantities of supply chain data. OMS technology needs to be capable of organizing (and making comprehensible) order management-related data, so multiple users across different geographical regions can do business. The big data trend also creates demand for AI applications that enable users to analyze and make use of specific supply chain and ordering management process data.

Order Management Process Data and Benchmarking

Capturing and organizing order management data empowers the decision-making component of the supply chain process. Having confidence in your supply chain analytics prepares you for solving future order management problems. Measuring internal order processing — order lead times, order frequency, cost per order activity, rate of return, and inventory accuracy — are best practices. Competitive benchmarking, which is assessing your order management, logistics, and supply chain performance against the best of class in the market is a popular strategy.

Benchmarking involves defining the opportunity or problem using a customer-centric model, acquiring, structuring, and filtering data, query analysis, testing for correlations and patterns, and applying the lessons learned. Competitive benchmarking requires continuous measurement of the order management process metrics (or key performance indicators) of your leading competitors. Keeping the customer experience and their perception of your performance is an integral part of benchmarking order process metrics.

Competitive benchmarking enables the incorporation of order management best practices based on industry standards. For order management professionals and other supply chain specialists, benchmarking provides a creative outlet for problem solving supply chain and logistic problem and protects against stagnant best practices. Benchmarking order management process metrics offers valuable insights for adopting new OMS technology.

Order Management and Value Chain Analysis

A supply chain association called the Supply Chain Council (now a part of APICS) created a standardized benchmarking framework called SCOR (Supply Chain Operations Reference). SCOR is a reference model based on the Porter value chain framework: supply chain, planning, procurement, manufacturing, order management, logistics, returns/retail, product design, research, prototypes, integration, launch, CRM, service support, sales, after-sale service, and contract management. Participating organizations complete an anonymous, detailed SCOR questionnaire designed around six common business service categories: Plan, Source, Make, Deliver, Return and Enable. For more information on value chain analysis, Porter’s value chain, and the SCOR model, read “How Your Business Can Benefit from Value Chain Modeling.”

Porter’s value chain modeling requires you to determine whether you are trying to differentiate or lower costs, prioritize changes with thorough analysis, and consider how changes to order management benefits the entire supply chain and business operations. According to Professor Martin Christopher, organizations find value by using value chain analysis to investigate and define the “logistics vision” of their organization.

In his book, Logistics and Supply Chain Management (5th Edition), Christopher recommends building a logistics vision around the question “How do we intend to use logistics and supply chain management to create value for our customers?” Christopher believes the best starting point for creating a logistics vision statement (and the purpose of this investigation into value) is “to give a clear indication of the basis on which the business intends to build a position of advantage through closer customer relationships.” By drilling down further and modifying the analysis specific to the order management process, value chain analysis can answer questions such as, “What order management activities do we excel in?” and “What differentiates us from our competitor’s order processing?”

Potential Order Management Software Benefits

Organizations look to technology for competitive advantages and solutions (for example, minimizing or removing manual steps or establishing centralized ordering system). The primary function of OMS technology is to convert customer data and order entry into action and provide management, sales, marketing, and customer service professionals a single-source of data, workflow, and communication. It enables companies to simplify the complexity of e-commerce and multichannel business.

Any organization with a product to ship, workflows to follow, and data to manage is a candidate to benefit from order management software. Whether you leverage Amazon, eBay, your website and warehouse, or a brick-and-mortar store or factory, the proper order management system helps solve problems and create value for your business. OMS applications can approve digital workflows (from desktop or mobile devices), automate inventory management, and speed up the purchase, procure and fulfill process to keep up with the digital customer experience. Some additional benefits often advertised by order management software vendors include the following:

- Sales Visibility: A fast, accurate order-to-delivery cycle requires real-time data to communicate order status, reduce backorders delays, and provide improved supplier response capabilities for product returns and exchanges.

- Optimized Inventory: An OMS keeps inventory levels up to date in a shared database. This single source of information helps to circumvent order delays and provide optimal restock purchasing data.

- Customer Satisfaction: Order management software provides easy-to-access order data like product descriptions, availability, and pricing. Keeping customers informed reduces order-to-delivery errors and order processing disruptions.

How to Choose the Right Order Process Management System

The digital economy changed customer expectations. The e-commerce market created an environment where information is expected to be made available to customers rapidly, and at any time. This dynamic makes choosing the right OMS technology critical.

Selecting the right OMS is a process involving a competitive market of of vendors that offer products by solution type (multichannel, e-commerce, or wholesale operations), deployment type (cloud or on premises), organization size, industry vertical, and geographic region, to name a few. Use the following steps to guide your selection process:

- Define Project Scope: This is a process of organizing your team to determine the high-level requirements of your OMS and overall project objectives, create project plans, gather stakeholders, and create a scorecard. For OMS, the scorecard might include criteria to evaluate the application features, support and service considerations, internal technical requirements, risk assessments, and cost of ownership.

- Identify Vendors: This stage involves creating a short list of potential OMS vendors and developing criteria to evaluate against your scorecard, and the high-level project objectives you established. Major players in the OMS market include Oracle NetSuite, Microsoft, IBM, Astea, IFS, ClickSoftware, ServiceMax, ServiceNow, eMaint, Hippo CMMS, Corrigo, Coresystems, Infor, Maintenance Connection, Loc8, MEX, Fingent, and ServiceChannel, Handshake, Amazon, Veeqo, Zoho, TradeGecko, and more.

- RFPs: The next step is to draft a formal request for proposal (RFP) memo and documentation that provides details for vendors to evaluate against their product and service offerings, request demos, and evaluate vendor references.

- Vendor Negotiation: After reviewing the RFP proposals submitted by qualified vendors, narrow the selection based on your completed project scorecard, including detailed analysis of product trade offs, pricing, service, and a competitive analysis. Negotiate changes with vendors and review updated terms. Ask questions about automated features, multichannel business capabilities, data reporting and analysis features, software innovation and third-party ecosystem integration, and software update and feature development schedules.

- Contract: The final step in selecting the right OMS involves coordinating installation and training schedules, determining final system deliverables and support plans, and drafting contract documentation.

Pave starts by determining his clients OMS needs by asking questions. “What tasks are you trying to accomplish with this software and what is most important to you today?” he asks. He also asks about the “nice-to have” features.

“It’s best to explore and document all possible use cases, prioritize these needs, and then examine the different solutions to see if anything exists that covers most or all of these tasks,” says Pave. “Doing so helps maintain a strict focus on the problem my client is looking to solve. It’s so easy to get caught up in what systems can do and so easy to forget that if the system you get can’t do what you bought it to do, it’s basically worthless.”

Because OMS business services affect multiple departments, Pave encourages people to start thinking about existing system integrations early in the selection process. This includes inventory, any logistics or product delivery systems, accounting or Configuration Price and Quoting (CPQ) systems.

“If you can set up your order system so that it automates as much as possible and eliminates double data entry and any risks for human error, you will be set up for success with shorter delivery times, higher customer satisfaction, higher rate-of-repeat orders, and more frequent orders,” says Pave.

Order Fulfillment Problems and Managing Order Management System Changes

Problems with your order fulfillment process and OMS technology threaten all aspects of your supply chain operations. In broad terms, the order fulfillment process includes steps in receiving, processing, and shipping inventory. The OMS links information systems to the physical process flow of order fulfillment. If there is a problem in demand forecast data, production flows, or inventory purchasing, order fulfillment is compromised. Problems with the order fulfillment process leads to problems across all business services and supporting systems. The following problems require changes to the order fulfillment process:

- Manual inventory handoffs

- Antiquated inventory systems that don’t interact with the OMS

- Limited visibility into order status

- Network outages

- Dependency on suppliers with antiquated systems

- Outsourced customer service operations

- Changes to product offerings

- New vendor technology

- Multiple responses to manual sales orders

- Failure to confirm pricing

- Problems configuring orders

- Inaccurate shipping addresses

- Problems sourcing inventory or carrier

- Delayed order entry changes

- Damaged goods or theft

- Calculation errors

If you break down order fulfillment into three broad processes of receiving, processing, and shipping, you see that an OMS platform or an integrated microservices architecture is capable of addressing order fulfillment challenges.

- Receiving: A common source of order receiving issues is outdated vendor systems without proper back office integrations to verify order accuracy. If a new product is received with changes to product packaging, the OSM manages the new information to calculate changes in inventory and delivery and restrict order processing. Whether it’s removing the need for manual processes to receive single orders or large batches, automated OMS features eliminate problems caused by human error.

- Processing: An integrated OMS solution provides a complete and detailed view of inventory and order status and prevents delayed order processing with automated features. Fallout management refers to the process of resolving a failed order processing event due to some task or order failure, like an empty shelf where inventory was indicated, from impacting the rest of the order processing flow. The OMS runs two types of fallout management programs: A hard point-of-no-return program prevents the processing of the next order until completion of the existing order process; no order changes are allowed at this stage. A soft point-of-no-return allows amendments to the order, but is programmed to notify customer of extra charges or change restrictions.

- Shipping: There is OMS technology that automates tasks like carrier selection, shipping label printing, and address verification to prevent order fulfillment delays at the last stage in the process. Automated shipping status notification services send customers updates about the shipping stage. To manage to after-sales experience, the OMS flags the email notification service to check in on the customer’s purchase or ask for a positive online review. Using this feature, the shipping stage of order fulfillment transforms into a customer-centric strategy for managing customer experience, and clear communication of the return/refund policy and procedure.

What Is Sales Order Management?

The term sales order refers to both an agreement between a customer and a business, and a document that captures the details and order data of a sale. Sales order management applies to the business processes, tasks, and documentation involved in generating this agreement. The sales order management process includes the following service capabilities and data:

- Sales quotes

- Order entry templates

- Order status notifications

- Product information

- Discounts, terms, and promotional data

- Customer relationship management

- Customer service representatives

- Shipping methods

- Payment processing

- Invoicing and receipts

- Cost of goods sold metrics

- Credit monitoring

- General ledger accounting

The sales order management system is involved with order entry, order system, payment processing, and records data. This system might communicate with an inventory management system to retrieve relevant data such as the item number, pricing, availability, and quantity discounts. Sometimes the term is interchangeable with the order management system (for example, Oracle Netsuite). The finance industry commonly uses "sales order management system" instead of OMS because there is no physical inventory for a separate system and the data managed is digital.

The Order to Cash Process

Order to cash (O2C) refers to the sequence of taking a sales order, preparing, processing, fulfilling, delivering, and invoicing the order, and then collecting money from the sale. The O2C process is typical in wholesale business and is used as a metric to measure healthy cash flow operations. In addition to maintaining a stable, reliable information system network and OMS, the O2C sales order management process includes the following requirements:

- Master Data: The accuracy of your list prices, products specs (dimensions, size, and weight), pack size, and freight details is critical. Communicate changes to this master data frequently and promptly.

- Terms and Conditions: Do not deviate from the standard terms and conditions of your customer's sales order process. Offer early payment discounts to build relationships and regularly review account performance with your customers. Contact customers as soon as an invoice is overdue (and do so consistently) so they prioritize your company.

- Bill-to-Cash: Learn your customer's billing payment methods. Do they pay as billed or deduct credits to compensate for money owed? Create an agreement up front to manage price promotions, reductions, and refund methods. Record credit notes regularly and accurately to correct invoicing and delivery mistakes.

- Customer Tendencies: Be proactive and learn your customer's order details – the frequency, typical order day, order size, regular promotions, and new product introduction process – to avoid delays in O2C processing.

Order Management Systems for Financial Securities

Financial markets use industry-specific OMS, sometimes referred to as a trade order management system, to manage financial securities trading activity. A financial OMS serves as an information system, database, and network connection that enables traders to enter and transmit orders to multiple execution points through electronic data interchanges (EDI) and track results. Firms conducting business electronically with OMS are called trading partners. Early systems used a primary spreadsheet style interface called a blotter. Trading partners managed pending orders and controlled how the OMS displayed and organized information.

A variety of financial OMS and trading system vendors popped up to serve the market with enhanced automatic execution (AutoEx) features and the ability to handle various order types (for example, limit orders). Foreign exchange traders could buy or sell securities day or night and manage orders automatically based on a wide variety of technical indicators – calculations based on the price, volume, or interest in financial securities. Implementing financial OMS produces accurate and timely data and frees up time and resources dedicated to monitoring and executing trades. OMS data reporting provides information about an investment portfolio's performance, composition, activities, and cash flows.

Buy-Side and Sell-Side Order Management Systems

The core function of financial OMS is to trigger buy or sell orders. Buy-side traders receive orders from a portfolio manager. The buy-side trader decides how to execute the order request and depends on the OMS to manage the order through the execution process. This process might involve trading partners known as sell-side traders. The trader either uses internal market data capabilities of the OMS independently or opens the information to sell-side interests to execute the order process.

Buy-side OMS has network connectivity with sell-side partners. Sell-side OMS uses open market exchange data connectivity to execute order processing. When a sell-side order is performed, the OMS updates data reported to the buy-side firm that originated the trade order.

The OMS provides information on open and previously closed orders. It provides a real-time network connection to market price streaming on global exchanges. To create competitive advantages, OMS vendors and internal development teams create advanced features using advanced technology and the fastest broadband networks. Firms use automation and AI algorithms for tactical asset allocation (TAA) – reallocating shares for market exposure – and to manage cash flow allocation, correct for market fluctuations, and track market trends.

Order Management Processing with the Financial Information eXchange Protocol

Sell-side OMS send requests to another intermediary (a dealer) using the Financial Information eXchange (FIX) protocol and may connect to other execution-management systems. The FIX protocol established a series of standardized messages that, when programmed into an OMS, ensure the words are handled electronically and without transcription errors. Financial regulations in the 1990s caused banks and financial firms to allocate more resources to obtain the correct trading data and adhere to new compliance metrics.

The FIX protocol links investment firms to the global banking and finance markets using OMS technology. The OMS employs the FIX protocol with a FIX engine that furnishes FIX messages between trading partners to communicate buy and sell orders accurately. Trading partners use different FIX standards to adopt the message types they use, so the FIX engine permits communication even if the OMS uses different versions of the standard. Trading venues use FIX messages to format order data for routing to sell-side or buy-side firm. The OMS uses internal market data to execute orders against the firm’s securities inventory. Otherwise, the OMS provides routing algorithms to send the order request to another trading partner.

A financial OMS manages order data such as the security identifier (ticker name), order type (buy, sell, or short), the number of shares, share class, order limit type, order instructions, and order transmission. The accuracy and availability of this order data are critical in securities trading to ensure that a firm's positions meet all regulatory investment guidelines. OMS infrastructure must maintain strict cybersecurity protocols to prevent network breaches and resolve service outages promptly. For this reason, there is still a mixed market for both on-premises and cloud-based OMS technology based on the infrastructure and resources of the firm.

Investment firms are graded on unrealized profit and loss, and pay capital gains taxes on realized profits and loss, so the accuracy and security of OMS data are critical. In the U.S., the OMS provides advanced functionality to provide tax lot assignments or record the price that an account received from aggregate order trading – hundreds or thousands of grouped small orders – to manage the shares of financial securities allocated to the individual accounts.

Build Powerful Order Management Processes and Workflows with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.