What Is a Construction Schedule?

A construction schedule is a timeline for a building project that construction managers use to determine the order and duration of construction activities. Construction schedules also track milestones, deliverables, and dependencies to help ensure projects stay on schedule and on budget.

Types of Construction Schedules

Construction managers can choose from many types of construction schedules. A team may also use multiple scheduling methods for one construction project. By understanding the differences between scheduling techniques, you can choose the most appropriate method for your construction project.

Review the following methods for building an effective construction schedule and consider which approach might best suit the needs of your project or team:

- Critical Path Method (CPM): Estimate the total completion time of a construction project by identifying all dependent tasks in your timeline. These are tasks that a team cannot begin until another task is complete. When using the critical path method, managers can anticipate changes to the completion date when there is a speed-up or delay in any critical path activity.

Learn more about how to use the critical path method for construction projects in our comprehensive guide. - Program Evaluation and Review Technique (PERT): Estimate the completion date of a construction project by factoring in optimistic, pessimistic, and most likely schedule forecasts. Managers start with a diagram of a building project, then use the PERT formula to weigh the most likely time estimate more heavily than the other two. This method reflects potential for the project to vary and is more sensitive to risk, which makes it especially helpful for one-of-a-kind or novel construction projects.

Find templates and learn more about applying PERT to your projects with our full guide to PERT. - Gantt Chart: Build a simple spreadsheet that lists each task needed to complete a project and tracks their progress over time. This document, called a Gantt chart, allows you to update future activities and completion dates based on actual progress. Construction managers like Gantt charts because they allow for a quick, high-level assessment of overall progress and make it easy to spot problems and delays.

Learn more about using Gantt charts and find helpful how-to videos with our guide to the basics of Gantt charts. - Line of Balance (LOB): Track actual progress against anticipated progress with a line-of-balance chart. This method is best for construction projects that involve repeated units of work, such as tall, multifloor buildings that require the same tasks for each floor. Using this method, managers can chart how long each repetition takes and predict the time needed to complete the remaining units. This method also helps managers adjust schedule forecasts as a team completes repeated tasks more quickly. This technique has limited value in projecting total duration of the critical path because it only takes into account the repeated tasks.

- Quantitative Scheduling: Schedule the use of materials and equipment at different locations in the most efficient way using the quantitative method. Also called Q scheduling or queue scheduling, this technique focuses on how the order of activities and the allocation of resources impact budget. This is a visual method that displays the quantity and duration of resources needed at different project locations at various times.

- Resource Scheduling: Prioritize efficient allocation of resources while also factoring in time, labor, funding, space constraints, and other important project details. There are two primary ways of dealing with resource constraints: Resource leveling allocates resources at a consistent level and adjusts the project schedule as a result. For example, rather than the crew working overtime, you would schedule workers for 40 hours every week and add weeks to the project. Resource smoothing, in contrast, prioritizes time constraints. In this case, you would either change project activities so that resource need does not exceed capacity or add more resources.

Find more tips and tools with our guide to resource scheduling. - Last Planner System: Use a holistic Lean approach that accounts for all the moving parts of a construction project. A trademarked approach, Last Planner System divides projects into five stages of planning. Master planning involves building a construction schedule for the entire project. During phase planning, managers make detailed schedules for each project phase, whereas in weekly work planning, they make schedules that can be completed reliably each week. The make-ready and learning phases help managers anticipate constraints and reflect on areas of improvement as a project progresses.

To learn more about the Last Planner System and other Lean techniques, see our guide to Lean project management. - Lookahead Planning: Prepare a project schedule that covers a short upcoming period, usually six weeks or fewer. As part of the make-ready phase of the Last Planner System, construction managers use a lookahead schedule to prepare for upcoming work. This process is usually incorporated into a weekly work plan.

- Master Schedule: Compile all high-level scheduling details for a construction project in a master schedule. This comprehensive, easy-to-read document specifies the major deliverables, individual work breakdown structure elements, and milestones for an entire project. Also called a level one, management, integrated master, or major milestone schedule, the master schedule is usually one page, includes a Gantt chart, and incorporates information from all aspects of the project.

- Milestone Chart: Summarize the major milestones of a construction project in a simple chart. Milestones are key events, deliverables, and important dates, rather than tasks or activities. Typical major milestones on a building project include permit approval, contract award, and final walkthrough.

- Schedule Baseline: Finalize and obtain approvals for a project schedule at inception that shows the targeted timeline for construction. By doing so, managers can have a basis of comparison for the actual progress that makes it clear when work is behind schedule. The baseline schedule does not update as the project progresses.

Find free construction schedule templates, including residential and two-week schedules, in our comprehensive collection.

What Makes a Good Construction Schedule?

A good construction schedule is realistic, accurate, and well-sequenced. It enables the project to stay under budget and takes into account resource and time constraints. By keeping an organized and accurate schedule, teams can make progress at a consistent pace without wasting resources.

Successful construction schedules are the result of input from all project participants. By encouraging open communication between management and employees, managers can set realistic scheduling goals, which keeps morale high, maximizes efficiency, and minimizes risk.

Implementing construction scheduling best practices promotes quality and safety and helps keep cash flow predictable. Poorly designed construction schedules, however, can lead to delays and cost overruns. Depending on contractual agreements, scheduling problems can even leave contractors vulnerable to penalties or lawsuits.

Check out our guides to construction project management basics and the art of construction planning to learn more.

Tips for Good Construction Scheduling

An accurate construction schedule is essential to a successful construction project, but building projects are complex, with dynamic conditions, task dependencies, and many participants. We’ve gathered advice from experts to help you prepare a construction schedule and avoid common pitfalls:

- Take the Full Scope of the Project into Account: Jim Brucato, President of Principle Construction Corp., advises construction managers to look beyond the building process. Pre-construction activities such as site acquisition, procurement, financing, and permitting have significant impact on the schedule. Clients may also have scheduling constraints that managers need to consider. If, for example, the building owner is leasing an alternative location and must vacate on a certain date, that restriction may dictate certain design and material choices. “These factors can shape a project. Start by making sure you understand the overall project,” Brucato urges.

- Acknowledge Supply Chain Issues: Product shortages and shipping delays impact construction schedules. Brucato says that supply chain issues require schedulers to build in additional lag time for tasks that might not otherwise require it. Adam Mopsick, CEO of Amicon, notes that supply chain issues have more than quadrupled lead times for some items and made others impossible to acquire. For example, in early 2022, the lead time for steel joists was 45 weeks or more; in comparison, three years earlier, the lead time was 4 weeks, according to industry data. Delays affect everything from HVAC materials to elevators, lighting, roofing, windows, and kitchen equipment. To mitigate this issue, builders might buy materials sooner and store them on site, commit deposits earlier, find alternative products, look for local suppliers at higher cost, or change specifications. When tasks are dependent on the receipt of materials, you might face a compound effect on delays. Schedulers should factor in this risk as they prepare timelines for their construction projects.

- Collect Data Diligently: Seek updated price, availability, and lead time quotes from vendors for every material in your project. Subcontractors should also go through this process, so your schedule is based on current conditions. “Be extremely proactive. Take nothing for granted. Make a phone call for every line item in the budget,” Mopsick advises. Similarly, check task duration estimates and work sequencing with all participants in the construction process. This can expose problems early and help you avoid major complications down the road. Keep good records of past projects, so you can use that information as a basis for scheduling similar activities.

- Pay Attention to the Standard and Unusual Parts of Your Project: A project with out-of-the-ordinary elements can be tricky to schedule. Avoid roadblocks by identifying these elements early on and factoring potential delays into the schedule. Examples include unusual site conditions, such as building on wetland that requires environmental review, or using a public-private financing model, such as tax increment financing, explains Brucato. “These can be very fluid and can derail your schedule,” he says. On the other hand, the pace of certain tasks, such as installing drywall, is predictable and can act as a standard reference to back up estimates.

- Know the Region: Local factors, such as weather, building codes, permit review processes, labor availability, other construction underway, union contracts, and wage trends, all influence the schedule of a construction project. As your portfolio grows, you will gain expertise on factoring local conditions into your schedules. For example, Amicon is active in South Florida, so Mopsick’s team knows how to handle scheduling around hurricane season.

How Do I Create a Construction Schedule?

Understanding the high-level process of creating a construction schedule is a good starting point for learning how to plan for your next project. The following are the five main steps to creating any successful construction schedule:

1. Gather Project Information

To create an accurate construction schedule, you need to know and understand every aspect of the project. This requires a thorough review of plans, specifications, budget, list of subcontractors, regulations on zoning and building codes, bill of materials, and procurement plans. Creating a work breakdown structure (WBS) will help you stay organized as you complete this process.

2. Select a Project Management Tool

A variety of construction-specific applications and software that make scheduling easier are available. Spreadsheets in Excel or Google Sheets are also excellent options. Lean toward tools that project participants already know, and consider ease of use for construction stakeholders. Communication features, available templates, and scheduling functionality are important criteria to consider when selecting a project management tool for any construction project.

3. Create a Draft Schedule

When drafting the initial schedule, make sure to factor in task dependencies and include buffers, extra time built into the schedule to account for unexpected delays. Add buffers to common sticking points, such as code inspections, and research seasonal or site factors that might influence the pace of work. By doing so, you can ensure that completion estimates are realistic before sharing your draft schedule with the client or stakeholders.

Tip: Mopsick says buffers will depend in part on the type of project and local conditions. Ask yourself whether the open date for this particular building is flexible or how long building permits take to acquire in this specific location. The best way to determine buffers is to review past projects with similar specifications.

4. Refine the Basic Construction Schedule

Share the draft schedule with stakeholders and confirm the viability of the schedule. Make sure you document all communications for later reference and include the procurement and lead times of all tasks in the work-breakdown structure and Gantt chart. Note any project milestones that affect release of financing. Once finalized and approved, this document becomes the project schedule.

5. Maintain Open Lines of Communication

Your schedule and Gantt chart will evolve as the construction project progresses. Keep the schedule up to date. Even if delays occur, you may be able to prevent them from impacting the project completion date by reallocating resources or adjusting other phases in the schedule.

Tip: Mopsick recommends holding regular meetings with project participants and agreeing upon means of communication. Updates can be sent via email or notifications in the project management tool. Whatever the method, it is important that everyone knows how they will receive information.

| Step | Tip | Pitfall |

|---|---|---|

| Gather project information | Be comprehensive and understand all ramifications. | Don’t overlook any aspect that could cause delays, such as material lead time or permitting processes. |

| Select a scheduling tool | Choose a tool that most people already know and is easy to use. | If you choose a complex tool, people may avoid using it, increasing the risk of schedule inaccuracies. |

| Draft a schedule | Add buffers to tasks that are prone to delays. | Double-check dependencies and the critical path. |

| Consult stakeholders | Make sure to get input from subcontractors. | Failure to check the draft schedule with project participants may result in last-minute problems that are difficult to resolve. |

| Refine and finalize schedule | Acquire and document all approvals for the schedule. | Make sure lead times are factored into the schedule to avoid delays. |

| Update as you progress | Hold regular meetings to exchange information. | Poor communication can lead to disputes. |

How to Create a Construction Schedule in Excel

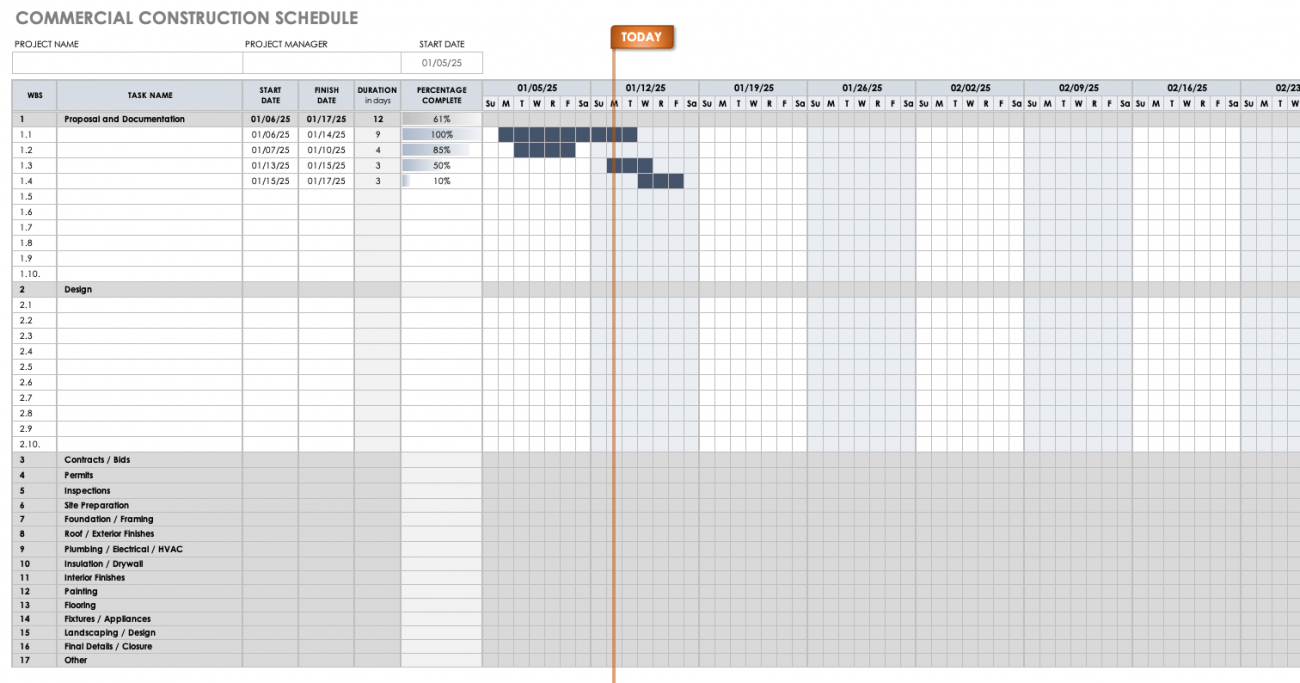

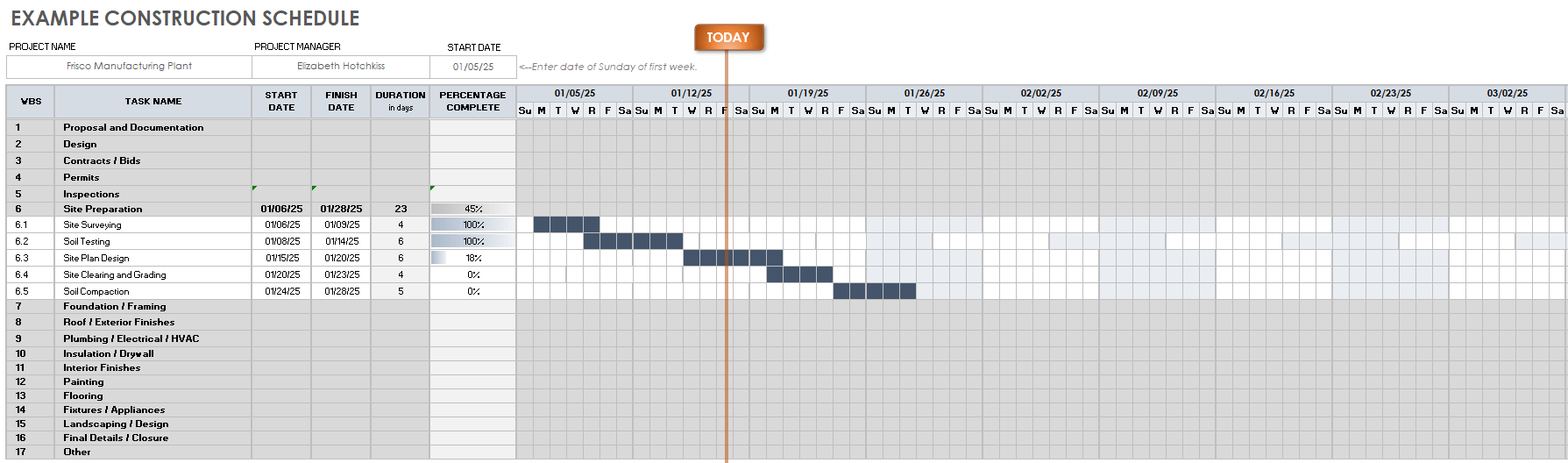

Download Commercial Construction Schedule Template — Microsoft Excel

This commercial construction schedule Excel template allows you to list project activities, start and end dates, duration, and percentage complete. Track the progress of construction with a built-in Gantt chart.

Follow the steps below to learn how to create a construction schedule using this template.

Enter Details for Your Project

- Download the Commercial Construction Schedule Template for Excel. The template should automatically open in Excel.

- Click cell B1 and replace the project title with the name of your construction project.

- Click cell B3 (Project Name) and type the name of the building.

- Click cell D3 (Project Manager) and type the name of the project manager.

- Click cell G3 (Start Date) and enter the date of the Sunday for the first week of the project. This will automatically populate the dates for each week in the columns to the right.

List Activities in the Construction Schedule Excel Template

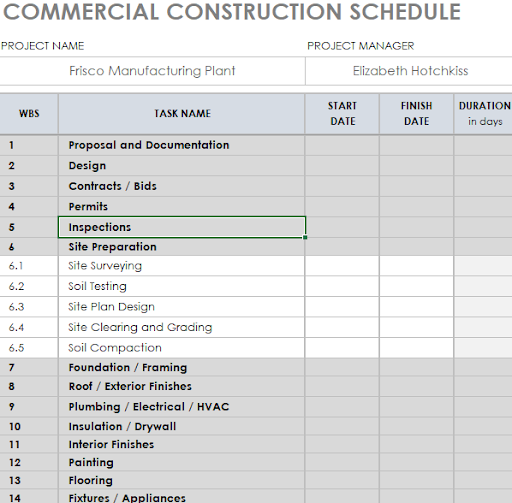

- Click the first cell (C7) under the Task Name column, delete the existing copy, and list the first work package from the work breakdown structure. Add each work package from the work breakdown structure to a row in the Task Name column. In the WBS column, enter the number of each major component as it appears in the work breakdown structure.

- Enter the subtasks for each work package in the Task Name column. Subtasks are identified with the parent’s number and a numeric extension. For example, site surveying is 6.1 as a subtask of site preparation.

Add Dates to the Task Rows and Calculate Duration

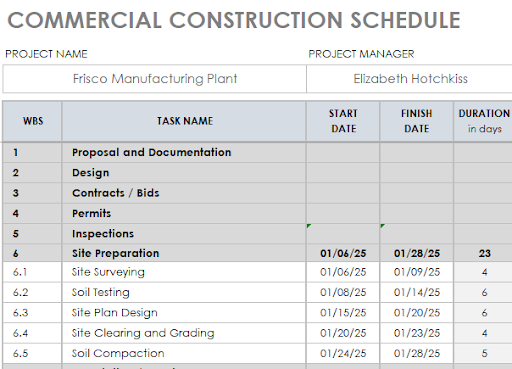

- On the work package line, in this case Site Preparation, enter the start date in the Start Date column.

Enter the start and end date of the first subtask (Site Surveying) in the start date column using duration estimates and dependency information from your planning documents. Repeat for each subtask in a work package. The Duration column automatically calculates the number of days from the dates. You can use this to check your schedule against your estimates.

Note: The template does not distinguish between working and nonworking days (such as the weekend). Durations may include nonworking days if holidays or days off fall in the middle of a task. This can be helpful if you find you need to bring in crews to work on days off to make up for delays. But this can also make durations appear longer or more variable than they are. - Enter the same end date for both the work package and the last subtask in the Finish Date column. In this example, the last subtask (Soil Compaction) is 1/28/25, so the finish date for (Site Preparation) should also be 1/28/25. The Duration column will show how long this stage is scheduled to last in its entirety.

Show Completed and Future Work in the Gantt Chart

- In the Gantt chart to the right, locate the corresponding dates to those of the start and end times for each work package and subtask. Select the cells that match the duration of a task or work project, then click the Fill icon in the ribbon and click a color.

- In the Percentage Complete column, enter the percentage of each task that is finished by comparing days of work done to total estimated duration. The template will automatically shade a portion of the cell that reflects the percentage.

- Click and drag the orange line to the current date so you can see your progress.

Customize the Schedule

- You can change colors, fonts, and other elements to suit your preferences by clicking the Home tab, highlighting the element in question, clicking on the relevant button (color, font, cell formatting, etc.) in the ribbon, and selecting new options.

- You can also click on a cell, right-click, click Format Cells, and choose new colors and other formatting options.

- Click and drag the borders of a column to adjust the width.

Construction Schedule Example

Download Example Construction Schedule — Microsoft Excel

Download this construction project schedule with sample text that shows how the template looks when filled out. This example gives schedule details for a manufacturing plant.

For more free, downloadable resources, see our comprehensive collection of construction timeline templates.

Master Scheduling with Smartsheet for Construction

From pre-construction to project closeout, keep all stakeholders in the loop with real-time collaboration and automated updates so you can make better, more informed decisions, all while landing your projects on time and within budget.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.